Joskin TRANS-KTP 9/11/15

|

|

|

Specifications

|

Model |

TRANS-KTP 9/11/15

|

Category Name |

Agriculture

|

Year |

2025

|

|

Stock Number |

A35

|

Sale Type |

New

|

Manufacturer |

Joskin

|

|

Odometer |

km

|

Price |

Contact for price CAD

|

|

|

|

Description

| A dump trailer to move mountains! |

| Specifications |

|

Payload (t)

9 → 15

|

Axle(s)

Single axle

Double axle

|

Range

Construction Dump Trailers |

|

General Points

The JOSKIN Trans-KTP 9, 11 and 15 T construction dump trailers are the ‘‘low-capacity‘‘ models of the JOSKIN professional heavy duty range. Given their compact and sturdy design (side walls and floor in HARDOX 450 steel), they are an ideal solution for smaller excavation works, landscape gardening contractors or even public services.

|

|

|

|

MODELS

|

Models

|

|

Model

|

9/45 |

11/45 |

15/45 |

|

|

4178-20 |

4179-20 |

4182-20 |

| Legend |

/ |

/ |

/ |

|

|

9/45 |

11/45 |

15/45

|

Body volume of the trailer

|

5,10 |

5,10 |

7,60 |

Technically permissible payload

|

9 |

11 |

15 |

Inside body length

Inner body dimensions (m)

|

4,50-4,60 |

4,50-4,60 |

4,50-4,60 |

Inside body width

Inner body dimensions (m)

|

2,18-2,26 |

2,18-2,26 |

2,18-2,26 |

Inside body height

Inner body dimensions (m)

|

0,50 |

0,50 |

0,75 |

Capacity of the tipping ram

|

19 |

19 |

27 |

|

|

ADR130X2000-10G |

ADR2X90X1900-8G |

ADR2X90X1900-8G |

| Brake drum |

406X120 |

350X60 |

400X80 |

|

|

| (1) The first 2 figures refer to the carrying capacity (in T) and the next 2 ones to the body length (in dm). |

|

|

FEATURES

|

Features

Design/Chassis

The chassis of the JOSKIN Trans-KTP 9, 11 and 15 T dump trailers is 900 mm wide and can therefore be fitted with wide wheels without exceeding a total width of 2.55 m. It is made up of 250 x 100 x 6 mm profile tubes on models 9/45 and 11/45, and of 300 x 100 x 8 mm profile tubes on model 15/45. The Trans-KTP 9, 11 and 15 T are fitted with an open drawbar that, given its structure, ensures a very good weight/resistance ratio. Furthermore, its wide fixing points (same width as the chassis) further improve the maneuverability. This solution offers a straight pull/push line and a large vertical clearance at the eyelet and thereby also absorbing shocks. Please note that the drawbar has a cross-suspension ensuring the driving comfort of the whole carriage. The “Y-shaped” drawbar provides a natural traction line and increases the stability of the dump trailer. This Y shape requires less power, and is therefore more economical and ecological.

|

|

Tapered, Light and Strong Body Tapered, Light and Strong Body

The JOSKIN Trans-KTP dump bodies are fully made of HARDOX 450 high tensile steel (4 mm on 9/45 and 11/45; 5 mm on 15/45) that has very interesting elastic characteristics. It returns to its original shape after deformation. Compared to traditional steel, the tensile limit is 5 times higher. All bodies are based on 2 steel sheets, without any linking cross-weld. Thanks to this manufacturing process, the empty weight of these dump trailers is significantly lower and therefore allows to transport higher payloads, without compromising on sturdiness. The tapered shape of the body (8 cm wider at the back) makes sure the contents of the trailer flow out freely. This unmatched property is further reinforced by the successive folds aiming at smoothing off the edges of the body. The bodies are short (4.50 m) and compact, with a low height (50 cm on 9/45 and 11/45; 75 cm on 15/45) to ensure an easy loading, whatever the size of the loader. The bodies of the KTP 9 – 11 – 15 range are all fitted with a pre-equipment for loading ramps and a double rear door.

|

|

2-Part Hydraulic Door 2-Part Hydraulic Door

The door can be opened manually by storing the 2 leaves on the sides (necessary to load a mini-excavator), or hydraulically by lifting the complete frame. With the hydraulic opening, the door has a large clearance for an easy unloading. With these 2 opening systems, there is always a solution adapted to your needs.

|

|

Safe Dumping Safe Dumping

The multi stage dumping cylinder is assembled on a double oscillating frame fitted with greased bearings and integrated in the chassis in a forward position. This system compensates the torsions due to the dumping strains and effectively protects the dumping cylinder and the body from distortions. The advanced position of the dumping cylinder also makes it quicker and easier to dump heavy loads. The back- and and upward position of the lifting hinges increases the unloading height. The standard safety valve, which is directly placed on the dumping cylinder, prevents the body from unexpectedly falling down (e.g. when a hydraulic hose breaks). The first two elements of the multi stage dumping cylinder are as a standard chromed. This anti-rust protection allows the body of the dump trailer to be left tilted backwards, especially during the resting time on a harvesting site, without the risk of rust pitting.

|

|

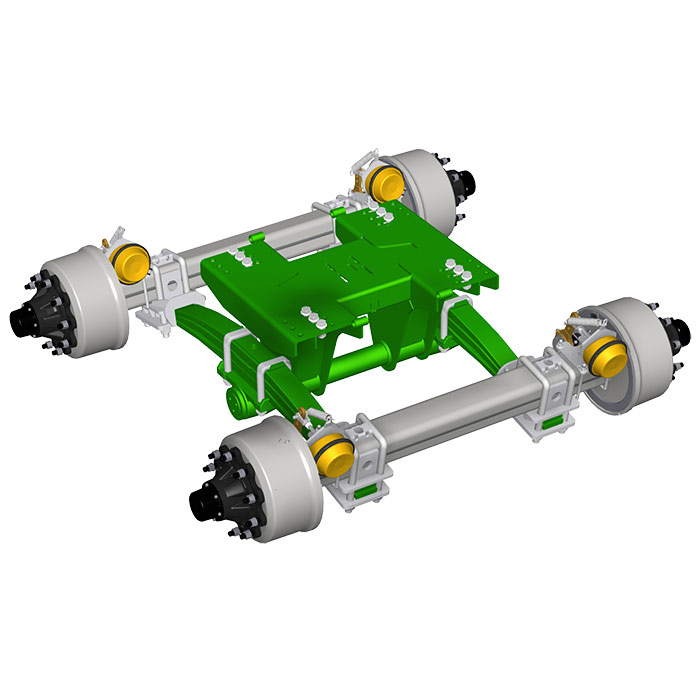

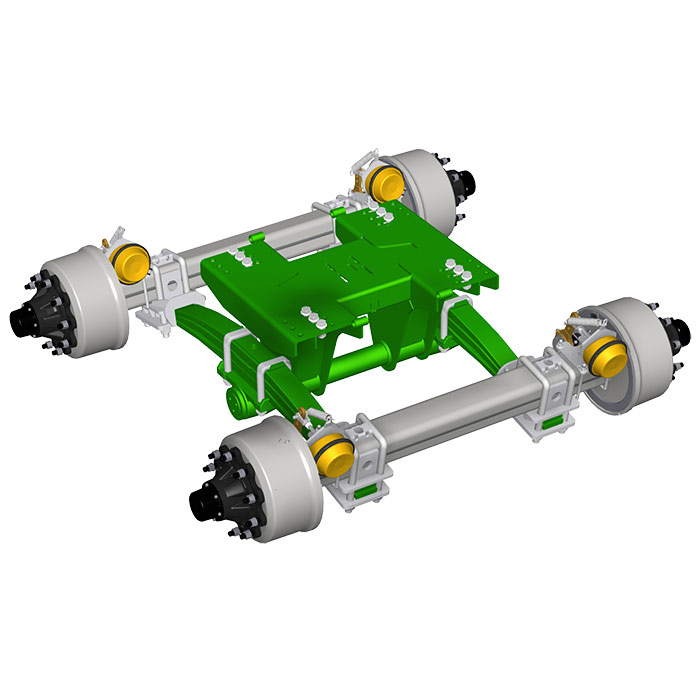

Movable Running Gear

All Trans-KTP 9-11-15 T dump trailers are fitted with a movable bolted running gear. This feature is particularly interesting because it allows to modify the weight on the eyelet, and thus on the back side of the tractor, especially when changing the tyres or the drawbar height. The Trans-KTP 9/45 are single-axle dump trailers with bolted axle brackets. The 11-15T dump trailers are standard fitted with a Roll-Over bogie with bolted table (clearance up to 24 cm).

|

|

|

SPECIAL FEATURES

|

Special_Features

Standard equipment

- Tapered monocoque body

- Automated welding and cutting

- Standard manufactured in special steel

- 4 mm floor and side sheets in HARDOX 450 except for 15/45: 5 mm

- One-piece side walls welded on the whole length

- Reinforced upper strip

- Door in high tensile steel

- Two part hydraulic door (DA)

- Door multi stage dumping cylinder integrated into the arm

- Body with pre-equipment for loading ramps

- Cross-suspension drawbar with parabolic leaves

- Bolted flat eyelet (Ø 50 mm) (small plate)

- Chassis width: 900 mm

- Chassis made up of profile tubes:

- - 250 x 100 x 6 mm on 9 and 11 T

- - 300 x 100 x 8 mm on 15 T

- Hydraulic skid

- Door opening and skid connected to one single DA with manual 6-way valve

- Oil-fed tipping

- Double oscillating frame for hydraulic tipping ram

- Air brakes

- Rear bumper

- LED double truck-type lights on oscillating frame (LED only available for brake and main-beam lights)

- Shot-blasting before painting

- Primer Ester Epoxy (2 K) + finishing lacquer (2 K) (total 100 µ)

- Forced drying (60°C oven)

- Wheels: 400R22.5 cover

|

Specific equipment Trans-KTP 11/45 and 15/45

- Bolted JOSKIN Roll-Over© bogie with parabolic leaves (length: 1.350 mm) on 11 and 15 T (1.600 mm leaves not available)

|

Specific equipment Trans-KTP 15/45

- Mudguards bolted to the body

- Galvanized front ladder

|

|

Tapered, Light and Strong Body

Tapered, Light and Strong Body 2-Part Hydraulic Door

2-Part Hydraulic Door Safe Dumping

Safe Dumping