|

Drawbar Suspension

All Ferti-Space2 muck spreaders are standard fitted with a drawbar suspension with silent-blocks. This system absorbs shocks and vibrations, and provides extra comfort to the user. As an option, this suspension can be replaced by a hydropneumatic drawbar. |

|

Versatile Wide Body

Versatile Wide Body

The monocoque body as well as various other components, such as the drawbar and the beater frame, are made of high tensile steel. This steel is characterised by its resistance and dynamic properties. It is thereby not necessary to add any body side reinforcements and it offers a considerably reduced empty weight. For maximum protection and therefore an increased durability, the Ferti-Space2 Horizon is also treated with a 2K industrial paint. The 1,050-mm or 1,350-mm high body (depending on the model) has a loading capacity from 12.32 m³ to 25.20 m³ (or even more if extensions are added). The moving floor consists of 4 Ø 14 mm marine chains with grade 80 (the highest grade in traction chains currently available) bolted to slats with (galvanised) closed profiles. It moves on a bolted galvanised floor, which can be replaced easily in case of wear. The moving floor is fitted with side tensioners that are easily accessible. The pulleys of the tensioners are made of cast iron and both moving floors are fitted with a central separator. Under the body there is a central corridor housing the hydraulic pipes as well as the electrical wiring in order to protect them from any contact with the transported material. In this way, the body forms a straight channel leading the manure towards the beaters. Since the spreading unit is wider (both inside and outside) than the body, the product can be distributed over the entire surface before being crumbled by the beaters and spread evenly by the spreading table. |

|

Low or High Tech Muck Spreader: it is up to You!

Low or High Tech Muck Spreader: it is up to You!

Your Ferti-Space2 Horizon muck spreader can be fitted with the modernest equipment. In this way, you can complete the functions of the standard Ferti-Control 4000 control box, which give you access to the electric control of the moving floor drive, a reverser of the moving floor direction, a control for the spreader hydraulics, the coupling of a DPA system and much more. Depending on your needs, you can also equip your muck spreader with a static or dynamic weighing system with digital display in the cab, an ISOBUS control box, GPS tracking, etc. "Everything" is possible. |

|

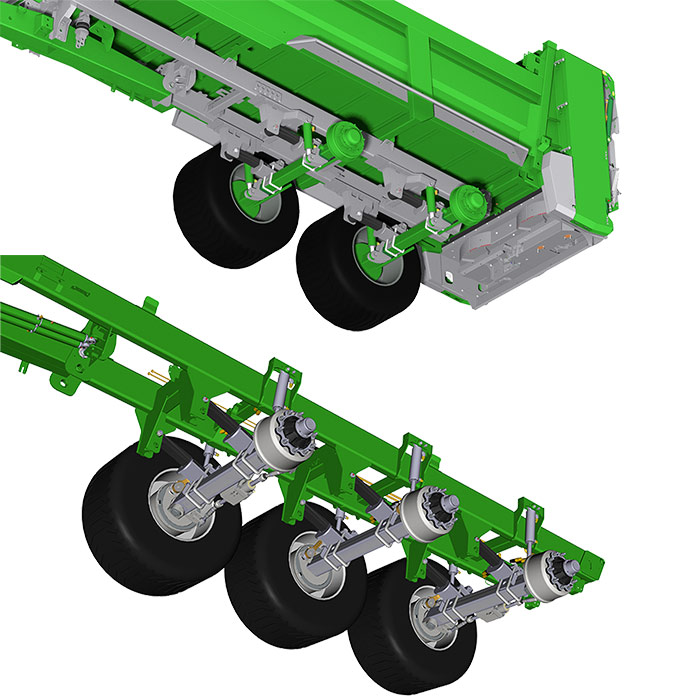

Running Gear

Running Gear

The running gear of the Ferti-Space2 muck spreaders has oversized axles for an optimal durability through time and powerful brakes in proportion to the high driving speeds (up to 60 km/h). Both the Hydro-Tandem running gear on the BU models and the Hydro-Tridem one on the TRU are bolted under the body. Since they can be moved, they allow to always keep a perfect balance with sufficient weight on the eyelet, regardless of the tyre configuration. This assembly or an assembly with wheels with a larger diameter is possible without any negative impact on the load distribution. The eyelet is also bolted and can be changed at any time without having to modify the structural elements. The Ferti-Space2 Horizon is standard fitted with a front lifting axle. In this way, when spreading, the operator can counterbalance the weight loss at the eyelet due to the material moving towards the back of the muck spreader in order to maintain an ideal traction. The Ferti-Space2 Horizon muck spreader is standard fitted with double-circuit air brakes. However, it is possible to get hydraulic or dual brakes as an option. |

|

Spreading and Beaters

Spreading and Beaters

The spreading width varies from 12 to 22 m, depending on the products to be spread. To achieve it, two horizontal beaters (Ø 600 mm on Ø 140 mm tube) rotate at a speed of 320 rpm to crumble the material that is brought to them. The teeth are in S700MC special steel (230 x 50 mm) and bolted for an easy replacement in case of wear. The crumbled material is projected against the closed spreading canopy to finally fall on the spreading discs (Ø 1,040 mm) rotating at a 500-rpm speed. The 6 adjustable vanes on the discs spread all the finely crumbled material evenly over a large width. If the material is too fibrous (such as fresh manure), the spreading canopy can be opened to 100° and allow the spreading work to be carried out mainly by the beaters. The flow per hectare is adjusted easily by combining the speed of the tractor with that of the moving floor, via the Ferti-CONTROL 4000 control box, and the standard (galvanised) guillotine door. The arms of the door are fitted outside the body for an optimal flow of the products. The beaters and the discs are driven by a wide-angle Walterscheid P.T.O.-shaft with overrunning clutch on the tractor side and cam security on the beaters side. The shaft drives a speed-increasing gearbox (Rögelberg) at 1,000 rpm, to which the two beaters and spreading discs are coupled. The spreading unit of the Ferti-Space2 Horizon is very high in order to ensure an easy passage and crumbling of any potential dome of material in the body. |